Bill of Materials and Custom Product Configurator

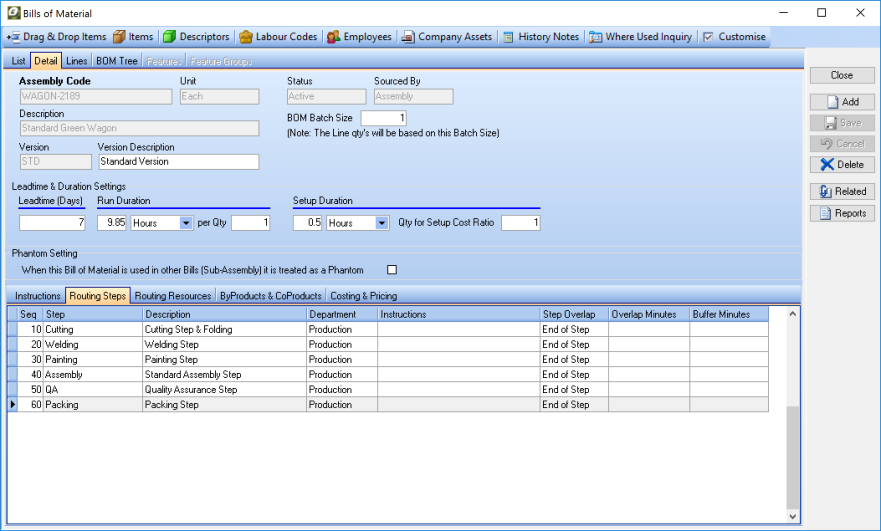

Bill of Materials (BOM)

- Simple or complex Bills of Materials (BOMs)

- Discrete or process manufacturing BOMs

- Make to order or make to stock

- Unlimited BOM levels with Tree View

- Calculate BOM costs based on batch quantity

- Optional Setup cost and amortisation over defined quantity

- Optional Routing Steps

- Standard operating procedure notes and documentation auto populate onto work orders

- Co Product and By Product

- Phantom BOMs

- Optional BOM line scrap %

- Tools and auxiliary equipment

- Overhead recovery and outwork

- Component “Where Used” inquiry

- Mass Replacement of components

- BOM Cost Rollup with Costed BOM reporting

- BOM change reporting

- Hazards for Bills of Material and manufacturing. Typical hazards for manufacturing will be related to material safety data sheets or handling instructions and the machinery or equipment used in the manufacturing process.

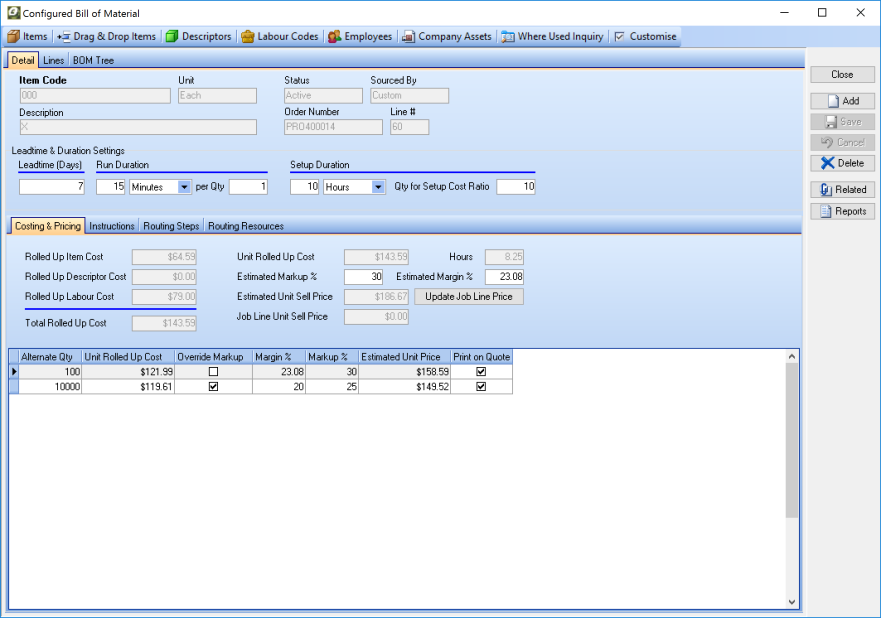

Custom Product Configurator

- Custom products with different cost per configuration

- Rules based configuration based on a series of defined questions and answers

- Configuration based on features and options based on a standard BOM

- Manually configured BOM which can be based on a standard BOM

- Different markup/margin per component or type of component in Custom BOM

- Import BOMs from CAD systems, spreadsheets or other files (requires customisation)