Manufacturing

Production Orders

- Create production orders manually, directly from an order or from Material Requirements Planning calculations

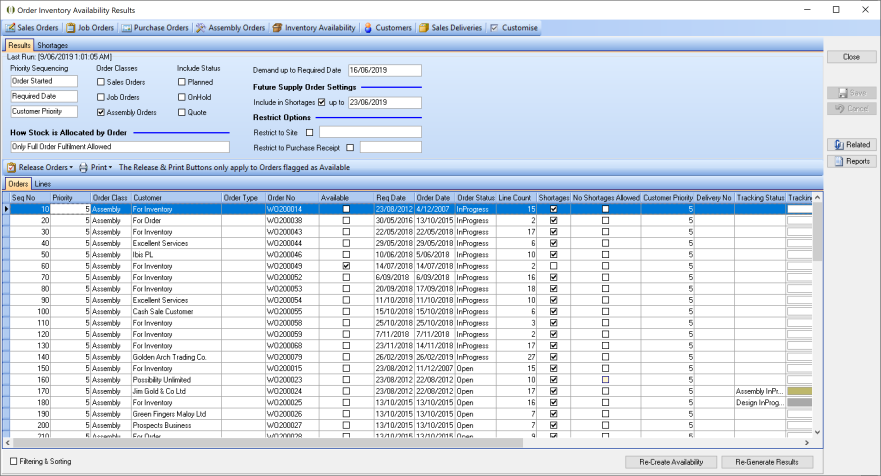

- Allocate available inventory to the highest priority production orders. Option to require no shortages.

- Check for shortages before releasing production orders to the shop floor

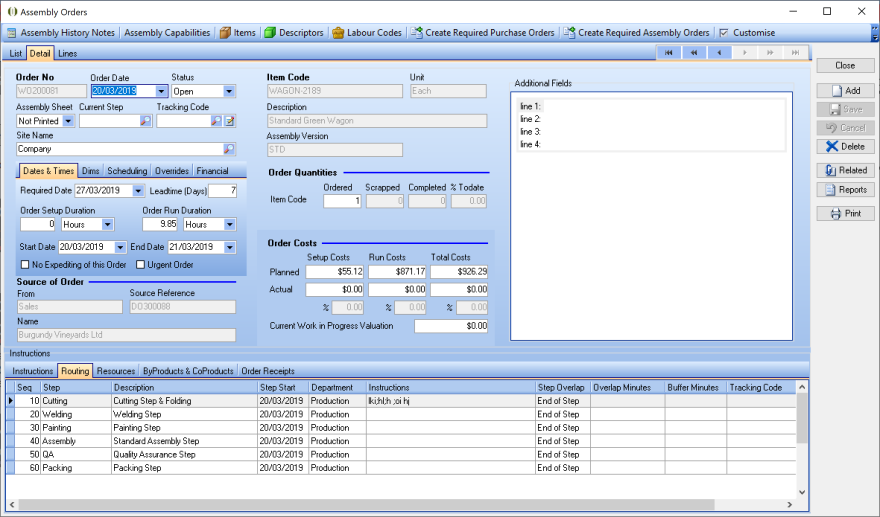

- Planned vs actual quantities and costs per production order

- Run and setup in elapsed time and labour/resource time

- Option to backflush production orders, ie auto issue components based on the proportion of finished goods receipted calculated from the BOM

- Scrap quantity with scrap codes

- Projected cost and hours to warn of overruns at any stage of the production order

- Raise Purchase Orders and Production Orders to Production Orders

- Purchases to production orders, (sometimes at a special price), can be issued to production orders immediately upon receipt, or can be kept in inventory reserved for that production order and issued to the production order as it is used. This can make Work in Progress (WIP) value more accurate when inventory is purchased to production orders in advance as it is not artifically inflated by purchases being issued to the production order upon receipt

- Outstanding production order purchase orders and supplier invoice reporting

- Manufacturing work in progress reporting