Ostendo Continuum (ERP) for Aluminium Joinery Production

Ostendo Continuum ERP – The Smart Solution for Aluminium Joinery Production

The aluminium joinery industry is fast-paced, highly customised, and fiercely competitive. From window and door fabrication to architectural glazing and commercial shopfronts, success depends on precision, speed, quality, and tight cost control. Ostendo Continuum ERP is purpose-built to meet the unique challenges of aluminium joinery production, giving manufacturers complete visibility and control from quote to cash.

Industry Challenges in Aluminium Joinery Manufacturing

Aluminium joinery producers face a unique mix of manufacturing and project-based complexity:

- Highly customised products with variable sizes, finishes, and configurations

- Rapid quoting and revisions for builders, architects, and developers

- Tight project deadlines and staged deliveries

- Complex bills of materials for frames, glazing, hardware, seals, and fixings

- Offcuts, wastage, and yield optimisation

- Compliance with Australian Standards and building codes

- Installation scheduling, site coordination, and after-sales service

Ostendo is designed to handle this complexity in a single, fully integrated ERP platform.

End-to-End Control from Quoting to Installation

Fast, Accurate Quoting for Custom Joinery

Ostendo Continuum enables fast and accurate quoting using configurable products and detailed bills of materials. You can manage:

- Custom window, door, and façade configurations

- Profiles, glazing options, colours, coatings, and hardware

- Automatic margin calculation and price updates

- Revisions and version control

- Conversion from quote to job without re-keying

This allows your sales team to respond faster while protecting margins.

Production Planning and Factory Floor Control

Work Orders and Job Tracking

Ostendo Continuum supports full job and production control for aluminium fabrication, including:

- Job creation and tracking

- Multi-stage manufacturing processes

- Batch and serial tracking

- Labour and machine time capture

- Progress visibility across cutting, machining, assembly, and glazing

Real-time job status ensures production supervisors always know what’s on the floor, what’s late, and what’s ready for installation.

Material Requirements and Yield Control

With rising aluminium and glass costs, material efficiency is critical. Ostendo Continuum provides:

- Automated material requirements planning (MRP)

- Aluminium profile optimisation and offcut management

- Purchasing custom glass sizes

- Hardware and accessory control

- Minimise waste and reduce emergency purchasing

Inventory, Purchasing, and Supplier Management

Ostendo Continuum gives you complete visibility across your supply chain:

- Real-time stock control of aluminium, glass, hardware, and consumables

- Automated reordering and supplier price management

- Lead time tracking for imported extrusions and specialty glass

- Landed cost and freight tracking

- Supplier performance monitoring (DIFOT, quality, reliability)

This ensures materials arrive on time to keep fabrication running smoothly.

Compliance and Quality Assurance

Aluminium joinery is tightly regulated and quality-critical. Ostendo Continuum supports:

- Quality inspection plans and checkpoints

- Non-conformance tracking and corrective actions

- Batch and lot traceability for glazing and coatings

- Compliance with AS/NZS building standards

- Documentation for warranties, certifications, and audits

Full traceability protects your business and gives builders and clients confidence.

Installation, Service, and Project Delivery

Ostendo Continuum bridges the gap between factory and site:

- Installation scheduling and crew allocation

- Delivery and logistics tracking

- Site progress updates

- Defects and variations management

- After-sales service and maintenance records

This ensures seamless handover from production to installation and ongoing support.

Mobility and Real-Time Reporting

With Ostendo Freeway mobile apps and live dashboards, your team can access critical data anywhere:

- Factory staff clocking jobs in real time

- Installers updating job status from site

- Managers monitoring KPIs on any device

Custom dashboards provide visibility into production efficiency, wastage, on-time delivery, and profitability.

Designed for Growth and Scalability

Whether you operate as a small custom joinery workshop or a multi-site architectural glazing business, Ostendo Continuum scales with your growth:

- Modular design – only pay for what you need

- Supports multi-company and multi-warehouse

- Handles high-volume residential and complex commercial projects

- Fully customisable to your unique business processes

Why Aluminium Joinery Manufacturers Choose Ostendo Continuum (ERP)

- Purpose-built for job-based and custom manufacturing

- Fully integrated from quoting to installation

- Eliminates disconnected spreadsheets and duplicate data

- Improves production efficiency and material yield

- Delivers real-time financial and operational visibility

- Supports compliance, traceability, and quality assurance

- Scales with your business as you grow

Transform Your Aluminium Joinery Operation with Ostendo Continuum (ERP)

In today’s competitive construction and fabrication market, aluminium joinery manufacturers need more than accounting software – they need a fully integrated ERP platform that connects sales, production, purchasing, installation, and finance in one system.

Ostendo Continuum ERP provides the control, visibility, and performance you need to increase throughput, reduce waste, protect margins, and deliver projects on time, every time.

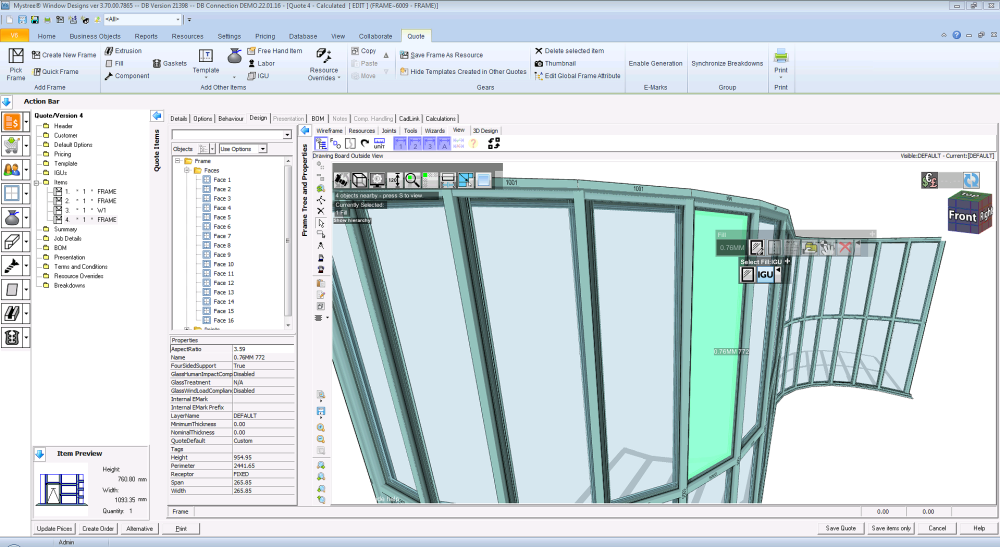

V6 for Windows and Doors

Our data exchange between Soft Tech V6 and Ostendo Continuum (ERP) delivers a complete solution for aluminium window and door manufacturers.

Click here for more information about V6 by Soft Tech