Scheduling & Capacity Planning in Ostendo Continuum ERP

(Click on the image to enlarge it)

Effective scheduling and capacity planning sit at the heart of profitable manufacturing, service, contracting, and distribution operations. Ostendo Continuum ERP delivers a powerful, flexible, and highly visual scheduling framework that replaces traditional whiteboards and spreadsheets with real-time, constraint-aware planning tools.

At the core of this capability is the Assignment Board—a dynamic, drag-and-drop scheduling environment that brings people, machines, assets, and jobs together in a single, live operational view.

The Assignment Board: Visual Scheduling That Works in Real Time

The Ostendo Assignment Board provides a graphical, Gantt-style interface designed to manage jobs, production orders, projects, deliveries, and service work with clarity and control. Unlike manual planning boards, it is directly connected to live ERP data, enabling immediate feedback, intelligent loading, and automated conflict detection.

Key capabilities include:

- Drag-and-drop scheduling of jobs, deliveries, and manufacturing orders

- Auto-refreshing schedules with real-time ERP data

- Visual warnings for conflicts, shortages, or capability mismatches

- Colour-coded tracking to highlight priorities, delays, or exceptions

This makes the Assignment Board ideal for both day-to-day operational scheduling and longer-term capacity planning.

Production Scheduling: From Simple to Fully Constraint-Based

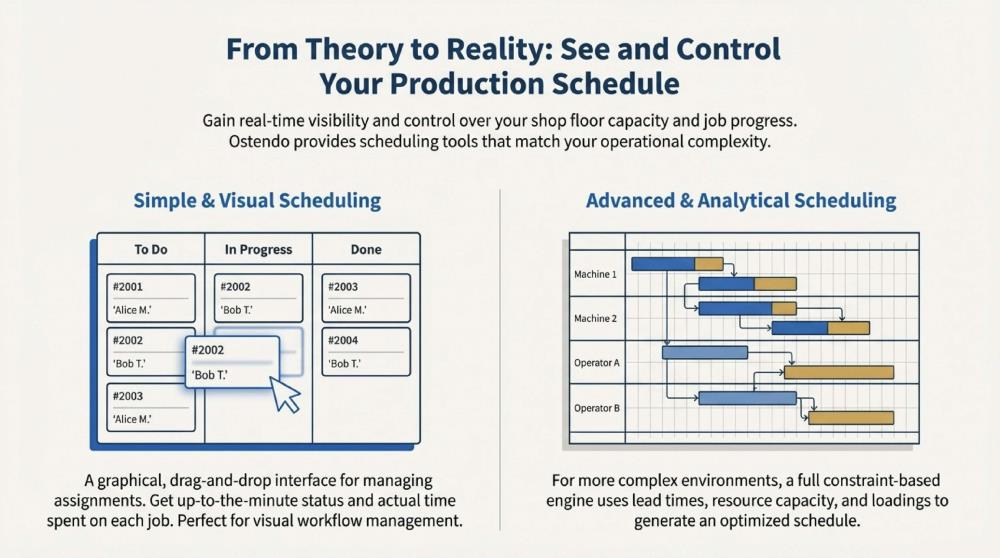

Ostendo Continuum supports a spectrum of production scheduling needs—from simple visual assignment through to advanced constraint-based planning.

Production scheduling features include:

- Constraint scheduling using lead times, resource capacity, and loadings

- Separate setup and run times for accurate planning, regardless of batch size

- Capacity loading analysis by day or week

- Scheduling by work centre, machine, or routing step

This ensures realistic schedules that reflect how your factory or operation actually runs, not just theoretical timelines.

Resource-Based Capacity Planning

Capacity planning in Ostendo is resource-driven. You define exactly what can be scheduled, when it is available, and what it is capable of doing.

Schedulable resources include:

- Departments

- Individual employees

- Teams or crews

- Company assets and equipment

Resources can have blocked times for leave, maintenance, meetings, or downtime, ensuring capacity plans remain achievable and credible.

Intelligent Rules, Warnings, and Visibility

Ostendo Continuum goes beyond simple calendars by embedding operational intelligence directly into the schedule.

Built-in intelligence includes:

- Capability rules to ensure only qualified staff or assets are assigned

- Visual warnings for double-booking, out-of-sequence tasks, or inventory shortages

- Highlighting of overdue work or exceptions using tracking code colours

- Options to automatically “bump” downstream work when schedules change

Planners gain immediate insight into problems before they disrupt production or service delivery.

Flexible Views for Every Role

Multiple Assignment Board profiles can be configured to suit different users and operational areas.

You can:

- View schedules by resource, order, project, or service zone

- Define what information appears on each Gantt bar

- Use multiple time scales, including workdays and work hours only

- Display actual timesheet hours against planned work

This flexibility ensures planners, supervisors, and managers all see the information that matters most to them.

Field Service, Projects, and Deliveries

Scheduling in Ostendo is not limited to the factory floor. The Assignment Board supports:

- Field service technicians by region or service zone

- Onsite installation and contracting projects

- Sales and distribution deliveries by carrier, run, or region

- Non-job activities such as inspections, meetings, or tool pickups

This creates a single scheduling platform across the entire business.

Mobility Integration with Ostendo Freeway

When combined with Ostendo Freeway Mobility, scheduling becomes fully connected from the office to the field.

Key mobility benefits:

- Dispatch jobs directly from the Assignment Board to mobile users

- Automatically update schedules as work is started or completed

- Allow staff to accept or decline assignments in the field

- Keep planners and field teams aligned in real time

The result is faster response times, fewer scheduling errors, and improved customer service.

Why Scheduling & Capacity Planning in Ostendo Continuum Delivers Results

By unifying scheduling, capacity planning, and real-time ERP data, Ostendo Continuum enables organisations to:

- Improve on-time delivery and throughput

- Maximise utilisation of people and assets

- Reduce scheduling conflicts and bottlenecks

- Respond quickly to change with confidence

Whether you are managing manufacturing operations, service teams, projects, or deliveries, Ostendo Continuum provides a scalable and intelligent foundation for operational planning.

Reporting & Analysis

Effective scheduling and capacity planning rely on clear, real-time visibility across people, machines, materials, and time. A strong reporting framework turns complex schedules into actionable insight—helping planners balance demand, optimise utilisation, and respond quickly to change.

Schedule Performance & Plan Adherence

Gain immediate insight into how well production plans are being executed.

- Planned vs Actual Schedules — Compare scheduled start/finish times against actuals

- Schedule Adherence (%) — Measure compliance by work centre, job, or project

- Job Status Visibility — Queued, in progress, waiting, completed, or delayed

- Critical Path Identification — Highlight tasks impacting overall delivery dates

Outcome: Fewer surprises, faster intervention, and improved on-time delivery.

Capacity & Resource Utilisation

Understand whether resources are under-loaded, balanced, or over-committed.

- Work Centre Load Profiles — Visualise capacity by day, week, or shift

- Labour vs Machine Capacity — Separate and combined views

- Utilisation Heatmaps — Quickly identify bottlenecks and idle capacity

- Finite Capacity Views — See the real impact of constraints on schedules

Outcome: Better load balancing and smarter allocation of constrained resources.

Bottlenecks, Constraints & What-If Scenarios

Move from reactive firefighting to proactive planning.

- Bottleneck Analysis — Identify recurring constraint points

- Queue & Wait Time Reporting — Measure non-productive time

- What-If Simulations — Test alternative sequences, overtime, or extra shifts

- Impact Analysis — See how changes affect delivery dates and utilisation

Outcome: Confident decision-making backed by data, not guesswork.

Demand, Throughput & Flow Metrics

Align capacity with real demand and business priorities.

- Throughput by Period — Output per work centre or product line

- Demand vs Capacity Trends — Short- and medium-term planning insight

- Lead Time Analysis — Planned vs actual cycle times

- WIP Visibility — Work-in-progress levels by stage

Outcome: Smoother flow, reduced congestion, and more predictable lead times.

Integrated Dashboards & Drill-Down Reporting

Turn high-level summaries into detailed operational insight.

- Planner Dashboards — Gantt charts, load graphs, and alerts in one view

- Supervisor Views — Real-time shop-floor status and exceptions

- Executive Summaries — Capacity risk, delivery confidence, and trends

- Drill-Down Capability — From KPI to job, operation, or resource level

Outcome: The right information, at the right level, for every role.

Exception Alerts & Proactive Visibility

Stay ahead of problems before they escalate.

- Over-Capacity Alerts — Early warning of overloads

- Late Job Notifications — Automatic exception reporting

- Resource Conflict Warnings — Prevent double-booking

- Change Impact Visibility — See ripple effects instantly

Outcome: Proactive control instead of reactive recovery.

Business Value

With strong reporting and visibility in scheduling and capacity planning, organisations achieve:

- Improved on-time delivery performance

- Higher resource utilisation with fewer bottlenecks

- Reduced expediting, overtime, and firefighting

- Greater confidence in commitments to customers

(Click on the image to enlarge it)