We can provide you with the systems and business processes improvement services to improve your business performance.

Driving Operational Excellence Through Business Process Improvement

With Lean Continuous Improvement at the Core

Every successful business—regardless of size, industry, or stage of growth—depends on well-designed, well-managed processes. When processes become inefficient, inconsistent, or fail to evolve with the organisation, productivity declines, costs rise, and customer experience suffers.

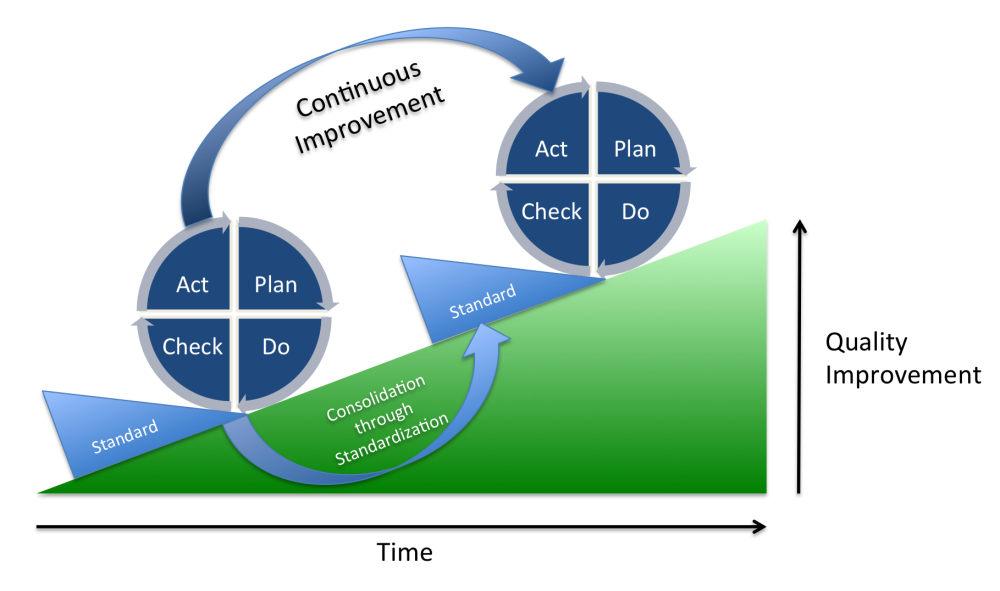

Business Process Improvement (BPI), supported by Lean Continuous Improvement principles, is the key to reversing this trend. By improving the flow of work through your organisation, eliminating waste, and standardising best practice, businesses can reduce costs, shorten cycle times, improve quality, and deliver better outcomes for customers and staff alike.

Why Improving Business Processes Matters

Even the best teams struggle when processes are unclear, outdated, or poorly aligned with how work is actually done. Inefficiency quickly becomes expensive—duplicated effort, rework, delays, bottlenecks, and preventable errors erode profitability and service levels.

Business Process Improvement enables organisations to:

- Streamline workflows and remove non-value-adding steps

- Reduce operational waste, rework, and unnecessary costs

- Improve service delivery and customer satisfaction

- Enhance product and service quality through consistent execution

- Create stable, repeatable processes that support scalability

- Establish a culture of continuous improvement

Effective processes form the foundation for predictable, high-quality outcomes—essential for long-term operational excellence.

Business Process Improvement Services

Every improvement journey begins with understanding how work flows today. We help you map, visualise, and analyse your current-state processes using proven tools such as flowcharts, swimlane diagrams, and detailed process maps.

From this analysis, inefficiencies, delays, and waste are identified. Future-state processes are then designed to improve flow, reduce variation, and support consistent outcomes.

This structured approach aligns strongly with Lean principles, including:

- Eliminating waste

- Improving end-to-end process flow

- Establishing clear ownership and accountability

- Embedding standard work as the baseline for improvement

Fully Integrated with Ostendo Continuum ERP

Our Business Process Improvement approach is tightly integrated with Ostendo Continuum ERP, ensuring improved processes are embedded into day-to-day operations—not just documented.

Key capabilities include:

- Workflow Mapping – Business processes are configured directly within Ostendo as structured, enforceable workflows

- Linked SOPs & Training – Workflows reference standard operating procedures, documentation, and training materials to support standard work

- Mobile Checklists via Ostendo Freeway – Step-by-step checklists ensure consistent execution and compliance at the point of work

- Custom Approvals – Embedded approval rules prevent errors, rework, and unauthorised actions

This ensures process improvements are sustained and continuously reinforced through the ERP system.

A Highly Experienced Consulting Team

Our consultants bring decades of combined operational, financial, and systems experience across manufacturing, distribution, construction, contracting, and accounting environments.

Their backgrounds include leadership roles in:

- Operations and Production

- Procurement and Supply Chain

- Logistics and Warehousing

- Sales and Customer Service

- Quality Assurance and Compliance

- Project and Job Management

- Construction and Contracting

- Accounting and Finance

This real-world experience allows us to design improvements that are practical, achievable, and effective—not theoretical models that fail in execution.

ERP + Sound Processes = Real Solutions

An ERP system alone cannot fix broken or inefficient processes. Technology simply amplifies what already exists. As the saying goes:

“Doing the same thing over and over and expecting different results is insanity.”

True improvement occurs when technology is paired with well-designed processes and a continuous improvement mindset.

That is why every Ostendo Continuum ERP implementation we deliver is treated as a Business Process Improvement initiative. We help you review, refine, and redesign processes based on:

- Opportunities revealed through ERP visibility

- Automation and workflow capabilities within the system

- Gaps uncovered during process evaluation

- Proven industry best practices

The result is not just new software—but a better, more efficient way of running your business.

Measuring Business Process Improvement with Business Intelligence

Continuous improvement requires visibility and measurement. Our Business Intelligence (BI) solutions provide clear insight into how your processes are performing in real time.

With the right BI tools, you can quickly understand:

- What work exists in the system right now

- Who is performing the work

- How long each process step takes

- Where delays, queues, and bottlenecks occur

- How performance is trending over time

This level of transparency enables your team to:

- Identify improvement opportunities

- Measure the impact of process changes

- Make decisions based on accurate, timely data

- Align KPIs with business and improvement objectives

What gets measured gets improved.

Turning Data Into Actionable Insight

Sustainable improvement depends on timely, reliable information. Our solutions capture meaningful data at the source and transform it into clear, actionable insights.

With this visibility, your business can:

- Monitor performance in near real time

- Identify emerging issues before they escalate

- Improve planning, forecasting, and resource allocation

- Support ongoing PDCA-style refinement of processes

When strong processes are supported by accurate data and embedded systems, continuous improvement becomes part of everyday operations—not a one-off project.