Continuous Improvement is a way of thinking that constantly strives to improve business performance.

In today’s fast-moving business environment, improvement is not a one-off project — it is a mindset. Continuous Improvement, guided by the principles of Lean Thinking and using the PDCA Cycle, helps organisations eliminate waste, streamline processes, and build a culture where every team member contributes to better outcomes.

Whatever industry you are in, embedding Continuous Improvement into daily operations leads to lower costs, faster turnaround times, higher quality, and greater customer satisfaction.

What Is Continuous Improvement?

Continuous Improvement is an ongoing, systematic approach to analysing processes and making incremental changes over time. Rather than relying on large, disruptive overhauls. Continuous Improvement encourages small, consistent changes that accumulate into significant long-term benefit.

Key characteristics include:

- A focus on value — ensuring every activity contributes to what the customer truly needs.

- Respect for people — empowering employees at all levels to identify problems and suggest improvements.

- Incremental progress — favouring small, frequent adjustments rather than occasional large initiatives.

- Data-driven decisions — using real information, not assumptions, to understand issues and measure outcomes.

Lean Thinking: The Foundation of Effective Continuous Improvement

Lean Thinking provides the principles that underpin Continuous Improvement. Originating from the Toyota Production System, Lean focuses on maximising customer value while minimising waste.

The Five Lean Principles

- Define Value - Clearly understand what the customer actually values — speed, quality, accuracy, price, or flexibility.

- Map the Value Stream - Analyse the steps involved in delivering your product or service. Identify activities that add value and those that create waste.

- Create Flow - Remove bottlenecks and interruptions so work can move smoothly through the process.

- Establish Pull - Produce or process work based on real customer demand, not forecasts or assumptions.

- Pursue Perfection - Continuous Improvement never stops — every process can be refined, simplified, and strengthened.

The Seven Wastes Lean Eliminates

Lean identifies seven types of waste (TIMWOOD):

- Transport

- Inventory

- Motion

- Waiting

- Over Production

- Over Processing

- Defects

Recognising these wastes in your workflow is the first step to reducing cost and increasing efficiency.

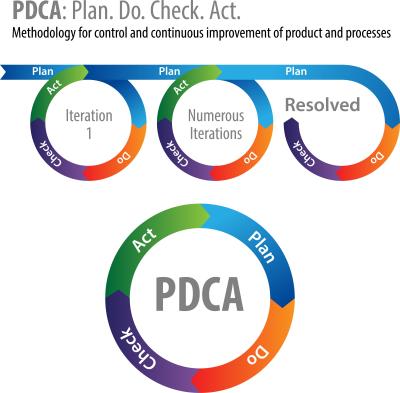

PDCA: The Core Improvement Cycle

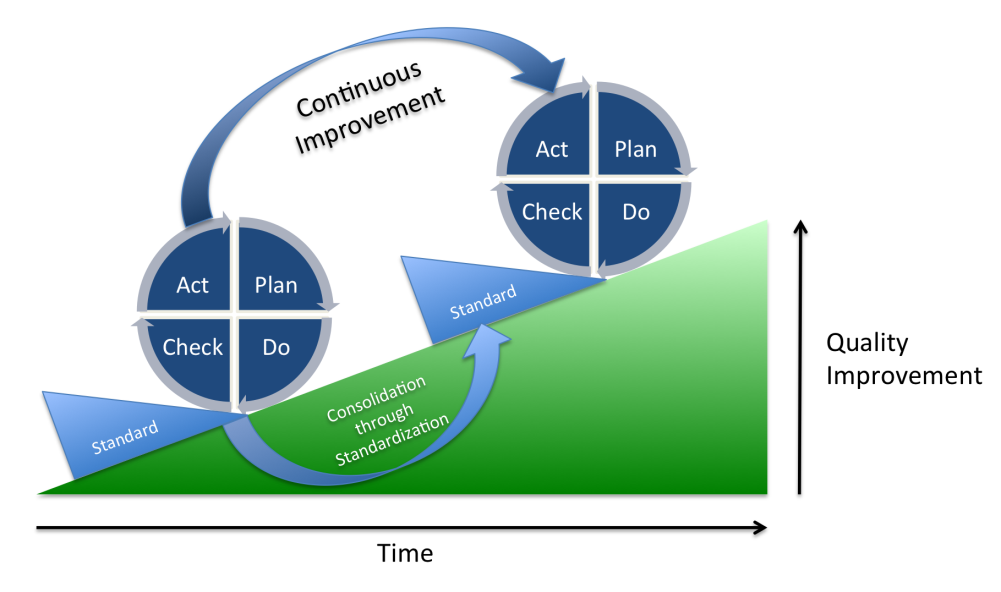

The PDCA cycle (Plan–Do–Check–Act) turns improvement from theory into action. It provides a structured method for testing ideas, validating improvements, and standardising success.

1. Plan

Identify a problem or opportunity. Analyse current performance, set objectives, and develop a clear plan for improvement.

2. Do

Implement the improvement on a small scale. Pilot the change in a controlled environment to gather data.

3. Check

Measure the results. Did the change produce the expected improvement? What can you learn from the data?

4. Act

If the results are positive, standardise the new approach and roll it out more widely. If not, adjust the plan and repeat the cycle.

How Continuous Improvement, Lean, and PDCA Work Together

These three components reinforce each other:

- Lean Thinking helps identify waste and opportunities.

- Continuous Improvement ensures change is ongoing and embedded in culture.

- The PDCA cycle provides the method for testing, validating, and adopting improvements.

Together, they create a powerful, sustainable improvement framework used by world-class organisations.

Benefits to Your Business

Implementing Continuous Improvement with Lean Thinking using the PDCA Cycle delivers measurable value:

Operational Benefits

- Reduced waste and inefficiency

- Improved workflow and process consistency

- Lower costs and increased profitability

- Better resource utilisation (people, time, materials)

Quality & Service Benefits

- More stable, predictable processes

- Higher product and service quality

- Faster response times and shorter lead times

- Fewer defects and errors

Cultural Benefits

- Empowered employees who contribute ideas

- A mindset of shared responsibility for improvement

- Stronger cross-functional collaboration

- Greater adaptability in changing markets

Embedding Continuous Improvement in Daily Operations

Success requires more than tools — it requires a culture shift. Here are practical steps to build CI into your organisation:

- Use visual management (dashboards, KPIs, workflow boards) to highlight issues early.

- Start small — focus on one process and demonstrate quick wins.

- Encourage frontline involvement — those closest to the work see the problems first.

- Integrate improvement into daily huddles or weekly reviews.

- Measure what matters — use data to track improvements, not assumptions.

- Celebrate success and make improvements visible across the business.

- Embed the PDCA cycle into projects, workflows, and decision-making.

When Continuous Improvement becomes part of everyday thinking, the organisation becomes more resilient, more focused, and more competitive.

Conclusion

Continuous Improvement is not a program — it’s a culture. By combining Lean Thinking with the PDCA cycle, organisations build an environment where problems are quickly identified, solutions are tested, and improvements are embedded.

The result?

A smarter, more efficient, more capable business — ready to deliver greater value to customers and achieve long-term success.

Experienced Team

Our team of consultants are highly experienced in operational and financials processes to help you implement Continuous Improvement projects in your business processes.

Their industry knowledge comes from practical experience over many years obtained from their work in manufacturing, distribution, service and contracting businesses or accounting practices.