Materials Requirements Planning (MRP) and Procurement

MRP (Material Requirements Planning) and Inventory Replenishment

- Minimum Quantity, Reorder Level, Lead Time and Days of Stock based on history

- Inventory usage forecast

- Inventory availability for sales orders, jobs and production orders based on required date, order priority and other factors to maximise best use of available stock

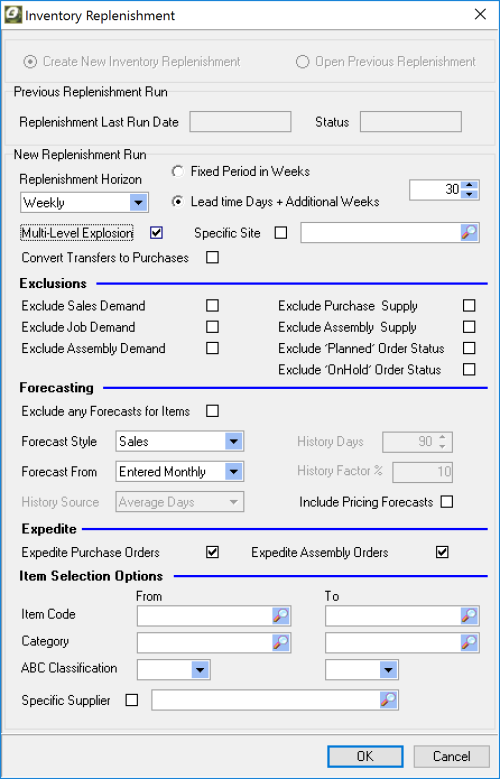

- Material Requirements Planning calculation with different methods and settings per company site

- Create purchase orders and production orders from MRP calculations

- Source on demand items create an automatic requirement for purchasing or manufacturing linked to the source record

- Create multi-level production orders through all levels linked to one sales requirement

- Replenishment and forecast reporting