Warehouse Management

Inventory Control

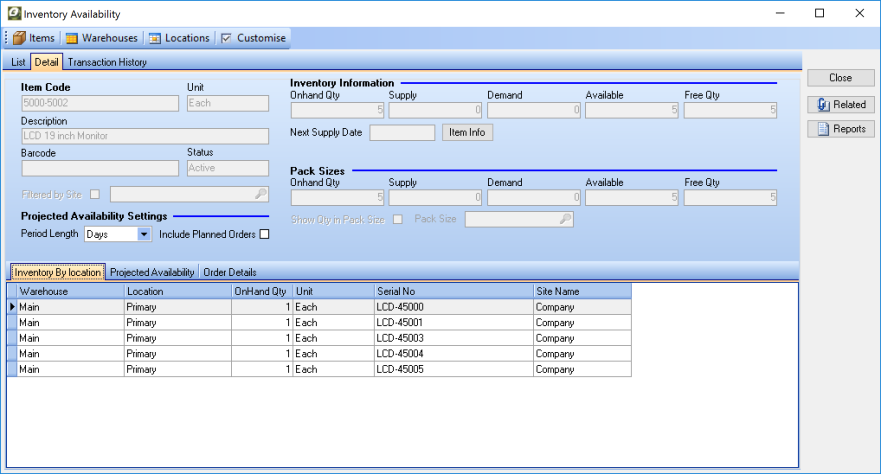

- Simple or advanced inventory control with optional hierarchy of site, warehouse and location

- Location code can be built on aisle, rack, row

- Location groups for different types of inventory, eg dangerous goods

- Inventory availability by location and projected availability

- Tracking by Serial No, Revision No, Batch No, Expiry Date, Grade, Colour, Size

- Barcoding, fully compliant with GS1 standard

- Consignment stock

- Negative stock options

- Inventory transfers with option for cost of freight spread over items

- Stock counts and Cycle Counting

- Stock counts by site, primary supplier or range of bin locations

- Stock count sheets in order of bin location, aisle, rack etc

- Inventory transaction history reporting

Ostendo Freeway Warehouse Management

- Hazards can be defined for inventory. Typical hazards for items will be related to material safety data sheets or handling instructions. Hazards are listed first in order of Risk Level (Extreme, High, Moderate, Low).

- New Hazards can be added from the Ostendo Freeway app.

- Control access to picking or handling certain types if items, eg dangerous goods, heavy goods etc.

- Instructions can be defined for items.

- Barcode scanning support for inventory including serial numbers or batch numbers.

- Inventory transfers from one warehouse and/or bin location to another.

- Pick inventory for manufacturing, jobs or sales orders and transfer them to a staging area or van.

- Count inventory with or without barcoding, from Inventory Counts created in Ostendo.

- Mandatory or optional checklists and data capture. A checklist is a pre-defined list of questions or pointers to guide a user and ensure that employees follow a disciplined and consistent process.

- Capture signatures with mandatory setting.

- Add notes.

- Use voice recordings instead of typing notes, or record noises for service purposes.

- Integrates with device camera to take photos or link to existing images on the device.

- Draw on photos to highlight points of note, or draw freeform sketches.